Automated Microbiology Streaking: Navigating Anaerobic Bacteria

Automated Microbiology Streaking

Navigating Anaerobic Bacteria Plating with Copan WASP and BD Kiestra

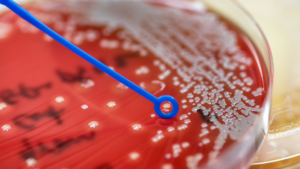

In today’s fast-paced clinical microbiology labs, automation is a game-changer for handling high volumes of specimens. Picture this: a busy shift where urine cultures, swabs, and blood samples pile up, and you’re relying on systems to streak plates consistently without the variability of manual work. Platforms like the Copan WASP and BD Kiestra have stepped up to make this possible, especially for anaerobic bacteria that demand careful oxygen control. But as helpful as these automated streakers are, they introduce challenges—particularly when it comes to media integrity during plating. Processes that expose plates to air can lead to oxidation, compromising results. That’s where specialized media, like Oxyrase’s OxyPRAS Plus plates, shine by resisting those pitfalls.

In this post, we’ll break down the systems, explore media options with their trade-offs, and see how enzymatic PRAS can make automation more reliable for anaerobes.

Understanding Automated Streakers in Anaerobic Plating

Overview of Copan WASP and BD Kiestra Systems

The Copan WASP, or Walk Away Specimen Processor, is a modular workhorse designed for liquid-based bacteriology. It automates everything from planting specimens to streaking with loops, prepping slides, and inoculating broths—handling up to 180 plates per hour. For anaerobes, it works well with tools like ESwab tubes, which preserve viability for short periods, but it falls short in any processing past the inoculation of the plate with the sample.

The Copan WASP, or Walk Away Specimen Processor, is a modular workhorse designed for liquid-based bacteriology. It automates everything from planting specimens to streaking with loops, prepping slides, and inoculating broths—handling up to 180 plates per hour. For anaerobes, it works well with tools like ESwab tubes, which preserve viability for short periods, but it falls short in any processing past the inoculation of the plate with the sample.

On the other hand, the BD Kiestra system, including its InoqulA module, uses rolling bead technology for precise, reproducible streaking. It’s part of a total lab automation setup that covers inoculation, incubation, imaging, and even result interpretation, with a media sorter holding up to 48 types. This standardization is a big win in clinical settings, reducing tech-to-tech variability. However, like the WASP, it can require manual tweaks for anaerobes, as automated handling will not immediately shuttle plates into oxygen-free environments.

Both systems boost efficiency and throughput, but their workflows—where plates might sit during sorting or streaking—can inadvertently expose media to ambient conditions, raising the risk of oxidation for oxygen-sensitive anaerobes like Clostridium or Fusobacterium.

Types of Media for Anaerobic Bacteria: Categories, Pros, and Cons

When plating anaerobes, the media’s reduction status is crucial because even brief oxygen exposure can hinder growth. Let’s look at the main categories, weighing their strengths and weaknesses in automated contexts.

- Non-reduced media are basic and inexpensive. They’re easy to prepare and store, but they’re a poor fit for anaerobes—the high oxygen content outright inhibits strict species, leading to false negatives or poor colony development. In automation, where plates might linger exposed, these are rarely viable.

- Post-reduced media start as standard but get reduced in anaerobic incubators after preparation. The upside is flexibility—you can reduce them on-demand—but consistency is an issue. The process is time-intensive, and any re-exposure to air quickly undoes the reduction, making them risky in high-throughput automated streakers.

- Pre-reduced media are treated to low oxygen levels before use, offering better support for anaerobe growth right out of the gate. They’re more reliable than non- or post-reduced options, with decent storage under controlled conditions. However, their stability is limited; they can oxidize if not handled swiftly, which is a common snag in automated delays.

- Traditional PRAS (Pre-Reduced Anaerobically Sterilized) media take it further by being both reduced and sterilized in an anaerobic environment. This ensures high reliability for culturing fastidious anaerobes, with good growth support. The cons? They’re pricier, have a shorter shelf life due to sensitivity, and can oxidize rapidly upon opening—within minutes in some cases—making them vulnerable in automated workflows.

Enter enzymatic PRAS, like Oxyrase’s OxyPRAS, which builds on traditional PRAS by incorporating an enzyme system to actively scavenge oxygen. This makes it the standout choice: it combines the reliability of PRAS with enhanced resistance to ambient air, allowing plates to withstand exposure without losing efficacy for up to 2 hours. Unlike the others, it doesn’t just passively maintain reduction—it fights oxidation dynamically, leading to better recovery rates and fewer workflow interruptions.

Learn more about enzymatic PRAS here.

Potential Detriments of Automated Processes to Media

How Automated Workflows Can Lead to Oxidation

Automated systems like WASP and Kiestra excel at streamlining lab processes, but the nature of their workflows can sometimes result in extended exposure to ambient air. For instance, during sorting, queuing, or transfer steps, plates may remain open longer than in manual handling. This allows oxygen to ingress, oxidizing the media and reducing its ability to support anaerobic growth.

The concern is particularly relevant for non-enzymatic media, where the reduction state can degrade quickly—studies indicate that standard plates might lose their anaerobic properties in just a few minutes under such conditions, turning an otherwise efficient process into one with potential reliability issues.

See how oxidation of media affects anaerobe recovery in our in house study.

Consequences in Clinical Settings

In practice, oxidation hits hard. It can yield smaller colonies or fail to isolate strict anaerobes altogether, forcing retests and delaying diagnoses. For example, in high-volume labs, this could mean higher error rates and wasted resources. Research highlights how non-PRAS options fare poorly in automated setups, with reduced isolation success for pathogens like Bacteroides—ultimately affecting patient care in scenarios like abscess or bloodstream infections.

The Role of Oxyrase’s OxyPRAS Plus Plates in Overcoming Challenges

Features of OxyPRAS Plus and the Oxyrase Enzyme System

OxyPRAS Plus plates are a prime example of enzymatic PRAS in action. They’re pre-reduced and anaerobically sterilized, but the real magic is the Oxyrase Enzyme System—membrane fragments that enzymatically remove oxygen. This allows the plates to resist oxidation for up to two hours in open air, far outpacing traditional media.They’re packaged in standard petri dishes, making them plug-and-play with systems like WASP and Kiestra—no special adaptations needed.

Advantages for Automated Applications

In automated workflows, OxyPRAS Plus tackles oxidation head-on by maintaining anaerobic conditions even during those inevitable delays in sorting or transfer. This leads to tangible wins: colonies can grow up to twice as large, recovery rates improve for tricky anaerobes, and the plates boast a 3-4 month shelf life for better inventory management.

From a lab perspective, this means fewer re-runs, lower costs, and smoother integration with automation. No more worrying about immediate incubation; the enzyme system buys you time without compromising quality. It’s particularly ideal for busy clinical environments where efficiency can’t come at the expense of accuracy.

Key Takeway

Automation with tools like Copan WASP and BD Kiestra is revolutionizing anaerobic plating in clinical microbiology, offering speed and standardization that manual methods can’t match. Yet, the risk of oxidation from workflow exposures underscores the need for smart choices in media categories like non-reduced, post-reduced, pre-reduced, and traditional PRAS, each with their own pros and cons. Enzymatic PRAS, exemplified by Oxyrase’s OxyPRAS Plus, emerges as the top option, providing robust resistance and better outcomes in automated settings.

If you’re optimizing your lab’s workflow, consider trialing these specialized plates. They could be the key to unlocking automation’s full potential while ensuring reliable results for your anaerobic cultures.